Process

S-Flex Coupling Choice Course of action

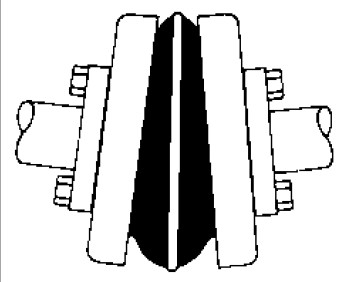

The assortment process for determining the proper S-Flex coupling involves applying the charts shown to the following pages. There are three parts to become chosen, two flanges and a single sleeve.

Data needed prior to a coupling may be chosen:

HP and RPM of Driver or working torque

Shaft size of Driver and Driven equipment and corresponding keyways

Application or tools description

Environmental problems (i.e. severe temperature, corrosive situations, room limitations)

Actions In Selecting An S-Flex Coupling

Phase 1: Decide the Nominal Torque in in-lb of the application by utilizing the following formula:

Nominal Torque = (HP x 63025)/RPM

Stage two: Applying the Application Services Issue Chart 1 select the services factor which best corresponds for your application.

Step three: Calculate the Style Torque of the application by multiplying the Nominal Torque calculated in Stage one from the Application Support Issue determined in Stage 2.

Style and design Torque = Nominal Torque x Application Support Factor

Stage four:  Using the Sleeve Effectiveness Data Chart two choose the sleeve material which best corresponds for your application.

Using the Sleeve Effectiveness Data Chart two choose the sleeve material which best corresponds for your application.

Step 5: Utilizing the S-Flex Nominal Rated Torque Chart 3 find the ideal sleeve materials column for that sleeve picked in Stage four.

Phase 6: Scan down this column for the 1st entry wherever the Torque Worth during the column is better than or equal towards the Design and style Torque calculated in Stage 3.

Refer on the greatest RPM value with the coupling dimension to ensure that the application necessities are met. Should the optimum RPM value is significantly less than the application requirement, S-Flex couplings are usually not suggested for that application.

Note:

If Nominal Torque is much less than 1/4 with the coupling’s nominalrated torque, misalignment capacities are reduced by 1/2. After torque worth is found, refer to the corresponding coupling dimension within the to start with column from the S-Flex Nominal Rated Torque Data Chart 3 .

Stage seven: Compare the application driver/driven shaft sizes to the maximum bore size out there to the coupling selected. If coupling max bore just isn’t significant enough for your shaft diameter, pick the following largest coupling that should accommodate the driver/driven shaft diameters.

Phase eight: Using the Item Variety tables, obtain the appropriate Keyway and Bore size demanded and find the number.