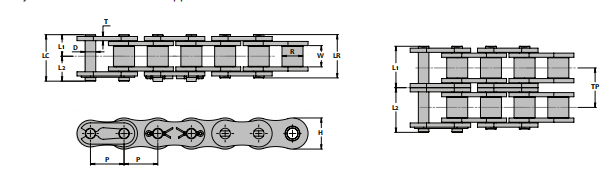

Common Data

We off er many different corrosion and/or temperature resistant roller chain solutions to suit the certain requires of pretty much any application. These vary from plated or coated carbon steels to several diff erent stainless steel forms  that could be chosen based mostly over the wanted mixture of wear resistance, strength, corrosion resistance and resistance to extremes in working temperatures.

that could be chosen based mostly over the wanted mixture of wear resistance, strength, corrosion resistance and resistance to extremes in working temperatures.

Nickel Plating

Ideal for mild corrosive circumstances this kind of as outdoor support. Frequently utilised for decorative functions. Chain elements are plated before assembly for uniform coverage of internal parts.

Form 304 Stainless

Our standard stainless steel product or service off ers excellent resistance to corrosion and operates successfully over a wide variety of temperatures. This materials is slightly magnetic due to the function hardening with the elements through the manufacturing processes.

Kind 316 Stainless

This materials possess better corrosion and temperature resistance compared with Sort 304SS. It’s normally utilized in the foods processing marketplace as a consequence of its resistance to pressure corrosion cracking inside the presence of chlorides this kind of as are found in liquid smoke. The magnetic permeability of this materials is incredibly lower and it is generally viewed as nonmagnetic however it can be not regarded as to get prspark oof.

600 Series Stainless

Pins, bushings and rollers are created from 17-4PH stainless steels which might be hardened for improved resistance to dress in elongation. The corrosion resistance of this chain is just like

Style 304SS. The operating temperature choice of this materials even so just isn’t as terrific as Kind 304SS.

Mega Chain:

A large power 304 stainless steel chain. Obtainable in two versions which use diff erent mechanical confi gurations to acquire added power. Both versions off er increased doing work loads resulting from a greater pin/bushing bearing area as well as a one of a kind labyrinth kind seal that assists avoid the penetration of abrasive foreign resources on the inner wearing elements.