Our AdvantagesProducts Big volume in Stock, No MOQ required We comply with all the international standards, such as ISO9001 and TS16949 standards.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, farms

- Gearing Arrangement:

-

Cycloidal

- Output Torque:

-

3.2-18000N.m

- Input Speed:

-

300-1800Rpm

- Output Speed:

-

0.16-1028r/min

Compared to other types of gears, worm gears are unique and have very distinctive characteristics and uses. This post will focus on the advantages of worm gears. For a list of common worm gear applications, please see worm gear capabilities.

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue

Supply Ability

- Supply Ability:

- 100000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden case

- Port

- Shanghai/Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 – 1 >1 Est. Time(days) 35 To be negotiated

Online Customization

Product Overview

Our linear actuators are always designed according to the mechanical requirements and characteristics of each tracker, and are mounted around the world working in different weather conditions.

Our range goes from 1.000N to load 200.000N.

Speeds from 400mm / min. to 10mm / min.

Wide range of mounting positions.

High protection degree to work in desert or high-level humidity environments.

In EP we specialize in adapting linear actuators to any solar tracker with the highest mechanical requirements.

Linear Actuators offer best fits for a variety of high-tech applications in Solar Tracking Control System Industry. Some of the more common applications include:

-

Solar Thermal Manufacturing Equipment;

-

Turf and Garden Equipment (tractors, cleaning machines, sky lifts, other utility vehicles);

-

Industrial Equipment (conveyors, adjustable work tables/platforms, hatch-doors-locks opening/closing);

-

Health – Fitness, Medical Equipment (handicap vehicles, wheel chairs, lifting units/beds, gym and therapy equipment);

-

Office and Home Equipment (automatic/garage doors, lifts, gates, satellite dishes);

-

Marine boats, ships, and oil rigs (seats, hatches, fire doors, rescue equipment, values, throttles);

-

Ventilation value controls, process Equipment, etc.

|

Product Name |

gear motor for shading system |

|

Worm geared motors |

Motor Worm Gearboxes |

Worm Gearbox For Automatic Car Wash Machine |

|

Worm gear units |

Lifting Gearbox |

Servo Worm Gearboxes |

|

Worm Gear Screw Lift |

Greenhouse Geared Motors System |

Worm Gear Drive Screw Actuator |

|

Stainless Steel Worm Reducer |

Motor worm gearboxes |

Worm Reducer For Construction Hoist |

|

Worm Gear Slew Drive |

Greenhouse Window Ventilation – Heat Curtain Reducers |

Worm Reducer For Paper Cutting Machine |

|

Slew drives for solar tracker |

Valve Actuators |

Worm Reducer For Dried Powder Press |

|

Worm gear linear actuator |

Two-Stage Valve Worm Gear Operator-V Type |

Worm Reducer For Rubber Tire Curing Press |

|

gear motor for glass greenhouse ventilation |

Multi-Steps Valve Actuator-H Type |

Worm Reducer For Pipe Welding Machine |

|

gear motor for shading system |

One-Step Valve Actuator-H Type |

Worm Gear Reducers For Hoists |

|

Motor Gearboxes With Rack |

Worm Gear Valve Actuator |

Worm Gear Reducers For Winch |

|

Motor Gearboxes With Winch Drum |

Low Backlash Right Angle Servo Worm Reducer |

Stainless steel worm gearboxes |

|

Pinion Drive For Greenhouse |

Special Worm Reducer For Tyre Changer |

Cast Iron Worm Reducers |

|

Motor Gearboxes For Greenhouse |

Worm Gear Operators |

RV Series Worm Reducer |

|

Motor Gearboxes For Hoisting Systems |

Worm Gear Box For Solar Tracking System |

Motor worm gearboxes |

Our Company

CNC workshop

Tooth profile workshop

Heat treatment workshop

Ginding workshop

Figuring center

CNC lathe workshop

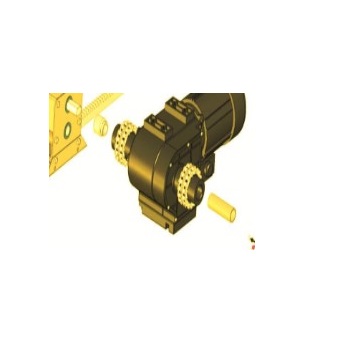

Close up of two yokes with the universal joint. Note the slight oozing of grease from the UJ seal ends, the clump of grease is from inside the yoke splined shaft area –Drive (outer) yoke has a female (usual spline) hole and “Y” shape end that is the universal joint (UJ) mount. –UJ is a cross shaped casting having roller bearings enclosed with caps at all four points and is held into the yoke with four “C” clips –Inner yoke and drive shaft is another yoke welded to the drive end, of the drive shaft. –Driven shaft and inner yoke is the driven shaft that rides inside of the drive shaft and has a yoke welded at the driven end –UJ another UJ as above

CNC teeth machine

Heat treatment machine

Gear teeth profile test machines

3D measurement machine

Our Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of

customization. For standard products, the payment is: 30% T/T in advance ,balance before

shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus,

MOQ and price may greatly vary with size, material and further specifications; For

instance, costly products or standard products will usually have a loEPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories. wer MOQ. Please

contact us with all relevant details to get the most accurate quotation.

Packing & Delivery

Follow Us